Celduc’s® innovative and highly efficient components are used to control all types of loads in many industries. The three major application areas are industrial heating and temperature control, lighting control, and motor control.

The advantages Solid State Relays (SSR) have compared to Electro Mechanical Relays (EMR) are well-known. Fully electronics, there is no moving parts inside SSR ; they have no audible noise, withstand significant vibration without operating problems, have fast response time, but most of all they have higher life-time expectancy. Used in appropriate operating conditions, SSRs have nearly unlimited life vs 100K cycles for EMRs. Thanks to their unlimited life-time SSRs don’t require any maintenance and prevent manufacturers from unforeseen machines/production stop, which is a great advantage nowadays with 24h/24 industrial activity.

Some of the Celduc® products meet the requirements of DIN EN60661-1(VDE 0750) for medical device applications as well as the requirements for "EX" protected areas and KOSHA (S-MARK).

Relays

Relays

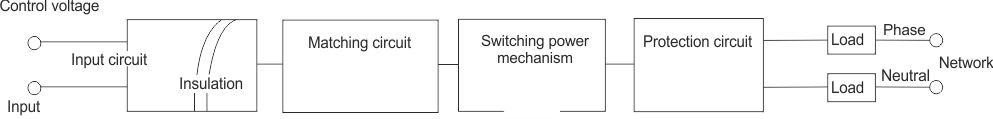

Solid state relays are switching devices made with electronic components. We use the word "relays" by analogy with electromechanical relays which have galvanic isolation of the control circuit and the switched circuit. “Solid state” refers to the fact that these devices do not have moving parts.A solid state relay switches a power (AC or DC) to a load and provides electrical insulation between the control circuit and theload circuit. This technology is in competition with or in addition to electromechanical relays and other switching technologies such as mercury switches and relays.

Advantages of Solid-State Switching:

- Long Life: Solid state relays do not have moving mechanical parts subject to wear and tear or deformation. When used well, a solid state relay has a lifespan 200 times longer than that of an electromechanical relay (EMR).

- Very low energy consumption:A low drive power will allow solid state contactors and relays to switch strong power loads.

- Silent operation:This technology does not generate acoustic noise while the outputs are changing state. This is a very important advantage for domestic and medical uses.

- Shock and vibration resistance: No risk of accidental switching with solid state technology.

- Very high switching frequency: Allowing a very high degree of accuracy for regulation(temperature, etc.)

- Other types of controls: (precise choice of the moment of switching) and possible diagnostic functions.

Zero-cross relay or random relay? - In the case of a zero voltage control (or zero-cross relay), power switching takes place only at the beginning of the alternation after the control has been applied. In fact, switching the power component is only permitted in the area around the zero crossing. In the case of resistive or capacitive loads, it is preferable to use zero-cross relays which in this way limit the di/dt, disturbances on the network and increase the lifetime of the load and the relay. In the case of an instantaneous control (or random relay), power switching takes place as soon as the control voltage has been applied (turn on time less than 100μs). This type of control is more suited to all high inductive loads because of the phase difference between current and voltage. It is also suited to systems requiring an immediate switching.

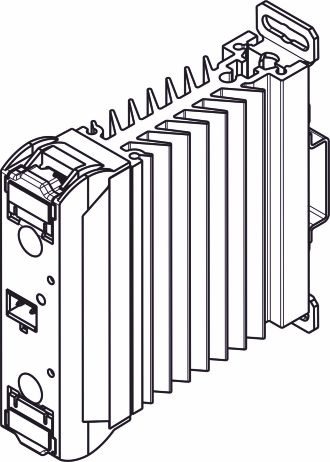

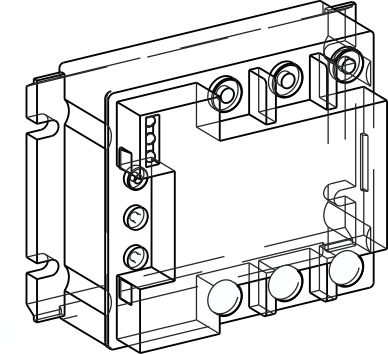

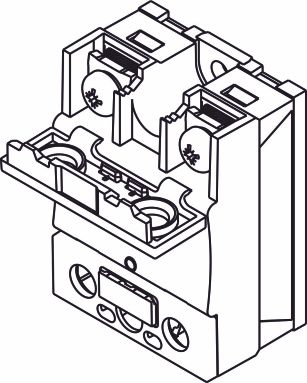

Thyristor rating vs. switching current - The switching components of solid state relays for alternating currents are thyristors. Solid state relays must be mounted on heatsinks in order to obtain nominal performance. “Thyristor rating”, which is an indication of the size of the power component, must not be confused with "switchable current" which depends on the construction and use of the relay or contactor. To match the switchable current by the relay and the application, it must refer to the tables and thermal curves in the technical datasheets for products that are not equipped as standard with heatsinks. Celducs solid state relays are fitted with back-to-back thyristors and use 4th generation TMS² technology with a very high life expectancy compared to themajority of products on the market.

Voltage protection - Strong dv/dts may appear at the solid state relay terminals. These can also be generated by mains interference or by the zero-cross current turn-off on inductive load. In relays adapted to most loads, Celduc uses high immunity components and sometimes an RC protection network. Overvoltages can also occur in the mains and cause the turn on of the solid state relay, even in the absence of control. To solve this problem, Celduc uses 1200 V or even 1600 V components, and, in certain ranges, includes a overvoltage limiter called a varistor or a VDR (Voltage Dependent Resistor), placed at the solid state relay terminals on the socket side. For relays suited to resistive loads, Celduc also offers an active limiter (TVS diodes on triggers) which closes the relay on an overvoltage to protect it.